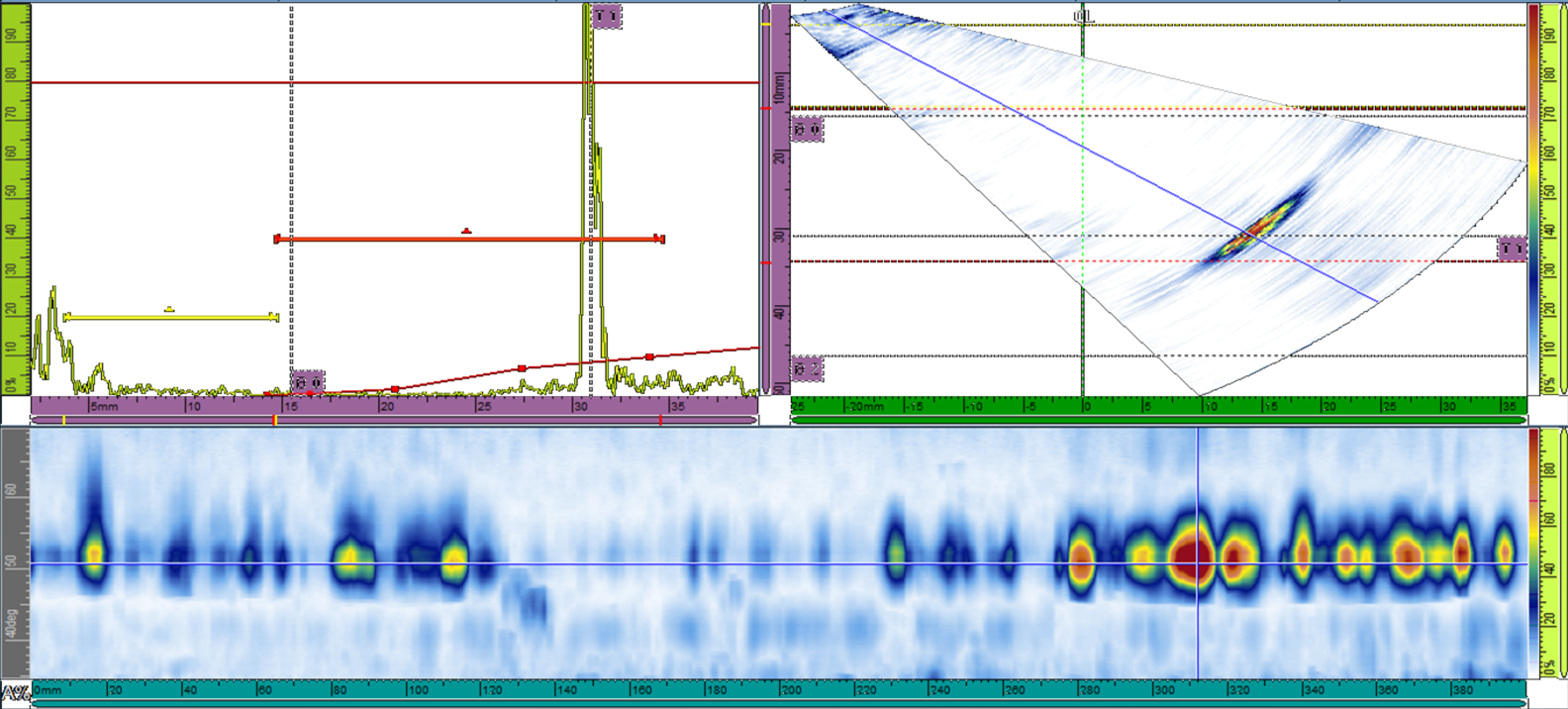

PAUT - Phased Array Ultrasonic testing is one of the advanced Ultrasonics methods, widely known for its higher probability of detection and precise measurement capability. PAUT has many advantages over other traditional ultrasonic and radiograpahic test methods. PAUT is Fast, Accurate, Traceable, Archivable

LMATS has capabilities to deliver the following expertise:

- PAUT Corrosion mapping to estimate thickness at finite points in pressure vessels, pipes, tanks and structures.

- PAUT on butt welds in pipes and pressure vessels and large structures.Bifurcation lines, Valve bodies, etc

- PAUT scans on complex geometries including painted cylindrical, trapezoidal fuel transport tankers

- Individually tailor development of qualification blocks, configuring rigs for data collection and levels of post-analysis reporting

- 100% weld volume coverage at scanning intervals of 1mm, of high pressure and high temperature piping welds at power station sites using encoded scanning on circumferential and seam welds between 20mm to 75mm wall thickness

- Inspection of small bore tubes - Internal diameter of down to 38mm; having a minimum wall thickness of 6mm

- Inspection of complex geometry branch welds with variable weld profile using encoded scanning for accurate sizing of internal defects

- Turbine and generator components inspections with special focus on areas of high stress concentration such as fur tree serrations of turbine blade roots and geometry changes along exciter cooling fans

- Detection of corrosion wastage in wind tower foundation bolts or other similar HOLD DOWN BOLTS with reliable monitoring of corrosion wastage along the length of bolts up to 5 times its diameter

- In-situ inspection of transverse cracks in shafts, axles, spindles, hold down bolts.

- Precise detection, measurement and reporting of smaller cracks for condition monitoring or repair.

- Inspection of various Aerospace CFRP (Composite Fibre Re-enforced Polymers) for delaminations and other discontinuities.

LMATS has developed several innovative PAUT solutions for odd shaped objects. One of the PAUT application developed by LMATS is shown below. The following photograph illustrates an unit which is designed and developed to examine mobile fuel transport tanks from outside painted surface to detect anamolies on the internal surface without emptying the tank.

This eliminates the need of emptying the tank followed by washing, drying for confined space entry for internal inspection. This innovative solution had eliminated downtime for the Asset owners increasing their productivity and thus saving operational cost.

This eliminates the need of emptying the tank followed by washing, drying for confined space entry for internal inspection. This innovative solution had eliminated downtime for the Asset owners increasing their productivity and thus saving operational cost.

LMATS provides on-site PAUT services from its laboratories in Melbourne (VIC), Sydney (NSW), Brisbane (QLD), Albury (NSW), Perth (WA), Newcastle (NSW). LMATS regularly performs on-site PAUT Victoria, New SouthWales, Queesnland, SA - South Australia, TAS - Tasmania, NT -Northern Territory, Western Australia and some of the countries in South-East Asia.

Contact us at one of the LMATS laboratories near you to discuss your requirements. Quick contact on phoneline +61 3 9399 8145 or via the online form