Inductively Coupled Plasma Atomic Emission Spectrometer (ICP-AES)

Inductively Coupled Plasma – Optical Emission Spectrometry commonly referred as ICP by the industry is a chemical analysis technique to measure elemental composition and concentration in various materials used in several industries. The ICP is versatile test technique for various applications in metallurgical, geological, environment and water, agricultural and food, organic, pharmaceutical and allied industries. The ICP chemical analysis is commonly applied on materials which cannot be readily analysed using other spectroscopy techniques. e.g. Spark OES and XRF Spectrometer. The ICP technique is perfect for dissolved or suspended solids in liquids, particulates, granular, agglomerates, soil, compounds, ores, trace elements in liquid, wine, milk, food, etc.

LMATS uses the latest technology Agilent 5900 SVDV ICP-OES where samples are introduced into the plasma in a process that ionizes and excites atoms, emitting electromagnetic radiation at characteristic wavelengths of each element. The wavelength intensity can be measured at concentrations as low as ppm and ppb levels. LMATS ' ICP is equipped with the Agilent IntelliQuant screening function that quickly screens samples and determines the approximate concentration of up to 70 elements from the periodic table. Considering the simultaneous analysis method and the attached auto sampler, LMATS can efficiently manage several samples a day ensuring quality results.

The ICP technique needs only few grams of sample to run multiple tests simultaneously. After the test tubes containing digested specimen are placed correctly in the auto sampler, the ICP can rapidly run an automatic program and identify desired elements and measure concentration level accurately for each element in each specimen instantly. Preparation of specimen includes dissolving a portion of material, contaminants, small specimens, and residues including drillings/burrs collected from live pipelines.

LMATS applies ICP analysis on the following regular industry applications

- Analysis of drillings/burrs from live pipelines for material confirmation and carbon equivalent determination for welding purposes

- Tiny metallic objects in confectionary, metallic filings in engine oil, or tiny residues from failed parts to assist with failure investigations

- Material analysis of samples that cannot be tested on the OES, such as manganese steels, nickel alloys, magnesium alloys, zinc alloys, titanium alloys and other rare and exotic alloys

- Analysis of heavy metals like cadmium, arsenic, lead and other potentially toxic metals and contaminants

- Analysis of geological and environmental specimens including soils, sediments, sludges, minerals, water and other organic matter

ICP for elemental analysis can be applied in the following range of applications

- Metallic alloys – High purity metals, Steel, Al, SS, brass, precious metals, solders, tin

- Geological - Coal, minerals, fossils, ore, rocks, sediments

- Industrial – Glass, ceramics, paint and coatings, polymers, packaging materials, fibres

- Petroleum – Oils, petroleum products, lubricants, fossil fuel etc

- Environmental– Soil, water, Brines, coal fly ash, dust, plating bath, sewage sludge, slag, seawater

- Agricultural – Food, fertilizers, roots, Animal tissues, beverages, feeds, nutrients, pesticides, plant materials, rice flour, soils, milks, vegetables, wheat flour, milk powder

- Organic - Adhesives, amino acids, antifreeze, combustion materials, cosmetics, cotton cellulose, dried wood, dyes, elastomers, epoxy, organometallic, organophosphates, organic solvent, sugars

- Other – Ash, acids, carbon, catalytic materials, electronics, film, phosphates, semiconductors, superconducting materials

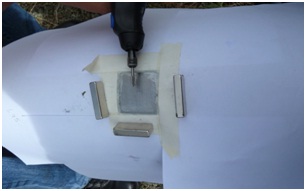

LMATS staff can also collect sample from live pipelines in the field or in-situ heavy machinery or structure using proven procedures to prevent contamination and perform lab based ICP chemical analysis.

Alternatively, LMATS can also perform onsite spark spectrometry on in-situ parts using LMATS portable O.E.S. that can also measure carbon content. For most in-situ solid metallic objects, LMATS portable XRF Spectrometer can be used to identify material and general chemical composition.

LMATS comprises a team of Metallurgist, Engineers, Scientist, Engineering Technologist and NDT personnel. The combination of these professionals from different specialty ensures that chemical composition along with several optional engineering tests results are interpreted by experienced metallurgists and the clients receive report, within the shortest period of time, on accurate identification of material grade for replacement of critical parts and or reverse engineering.

LMATS offer spectrometry services from our Melbourne, Albury, Sydney, Newcastle, Brisbane and Perth laboratories. These laboratories also provide services to the clients in Tasmania, South Australia, Northern Territory and New Zealand. Please contact one of the LMATS laboratories near you to discuss your material analysis requirements with one of the engineering professionals and obtain free advice on the best analytical technique.