Eddy current crack & flaw detection (on painted surface)

LMATS performs eddy current crack and surface flaw detection test on various caoted (painted) engineering components such as in-service painted structures, walls, beams, pipes, coloumns, welds, forgings and wrought products, heat exchanger tubes and similar products. LMATS test procedures are based on various National and international Standards such as AS 4544, ISO 17643, ASME V Article 8.

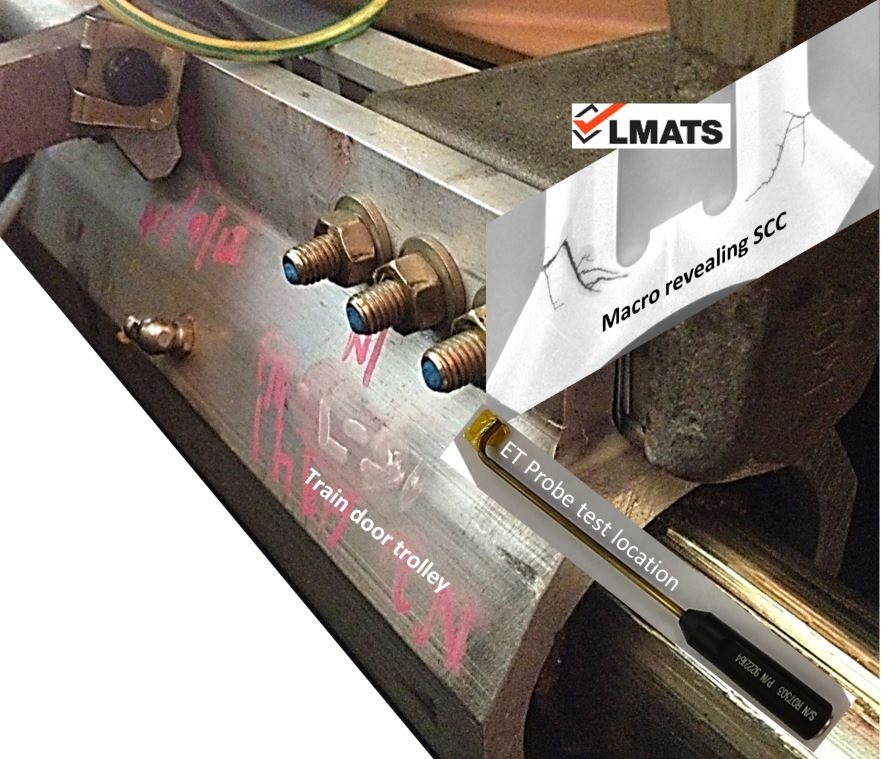

Eddy current crack detection is performed on several painted steel structures and non-coated Aluminium and Copper alloys. Refer to the following photograph showing an example of LMATS staff detecting SCC - Stress Corrosion Crack in a train door trolley using a right angle probe. Access to this trolley is very limited and only the probe can be inserted between the train door and the trolley.

Contact one of LMATS Laboratories nearest to you to discuss further about your project. LMATS offers Eddy Current testing and Advanced Eddy Current Array ECA from Melbourne (VIC - Victoria), Albury, Sydney, Newcastle (NSW - New South Wales), Brisbane (QLD - Queensland) and Perth (WA - Western Australia).