Poly Pipe Weld Testing of Butt and Electrofusion welded pipes.

LMATS regularly performs NATA accredited Poly Pipe Weld testing to ISO 13953 and ISO 13954.

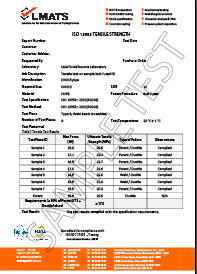

- ISO 13953 – Polyethylene (PE) pipes and fittings, Determination of the tensile strength and failure mode of test pieces from a butt-fused joint

-

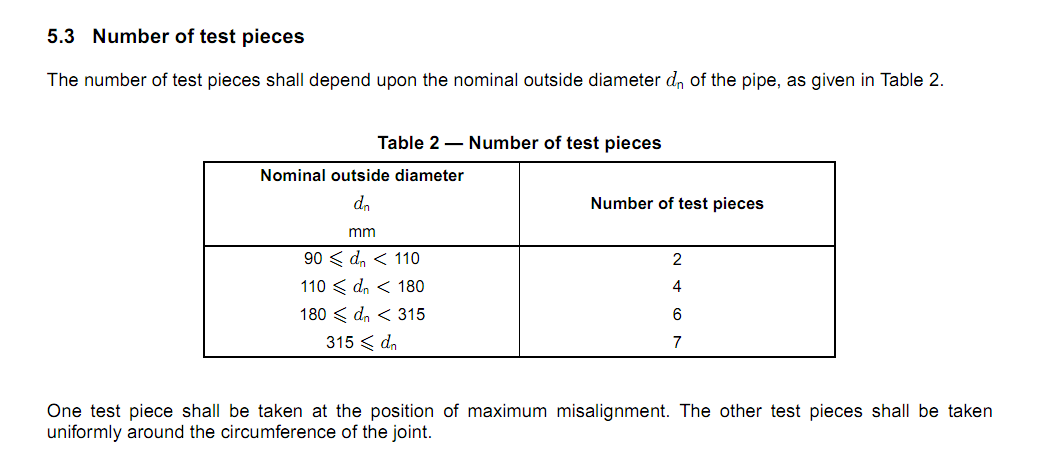

ISO 13954 – Plastics pipes and fittings — Peel decohesion test for polyethene (PE) electrofusion assemblies of nominal outside diameter greater than or equal to 90 mm of plastic pipes and fittings.

LMATS Poly Pipe Weld testing services

- Poly Pipe Butt Weld Tensile Testing

- Poly Pipe Electrofusion Decohesion and Debonding

- Poly Pipe Electrofusion Weld Tensile Peel

- Using our latest computer-controlled waterjet cutting machine the test samples are quickly and accurately produced thus giving our customers a very fast turnaround in their reports

- The LMATS Waterjet cutting machine:-

- Has a fine hair-thin pure waterjet, ideal for cutting soft materials,

- And also having the strength to cut through the hardest of materials,

- while maintaining the accuracy and quality of the cut with the infinite control of pressure up to 60,000 psi [4,150 bar].

Poly Pipe Butt Fusion Weld ISO 13953

Poly Pipe Butt Fusion Weld ISO 13953 Poly Pipe Peel DeCohesion Test ISO 13954

Poly Pipe Peel DeCohesion Test ISO 13954Why Use LMATS

The LMATS advantage of using Waterjet cutting technology:-

- Fast turnaround of results Next day reporting available!

- Poly Pipe wall thickness is not a problem, whether it is 3mm or 80mm LMATS limits testing to 150mm. The waterjet cutting technology enables LMATS to have a fast turnaround time

- The Waterjet cutting machine has a capacity of cutting up to 250mm thick

- No heat-affected zone (HAZ) in the plastic Poly Pipe sample

- Highly accurate and repeatability cutting

- The LMATS Waterjet Cutting machine has an Accuracy / Repeatability of 0.0025"[0.064 mm] and Linear Straightness of ±0.005 in/3 ft [±0.13 mm/m].

- No distortion used cold cutting technology, thus eliminating changes in mechanical properties of the specimen due to thermal effects

- Large cutting deck (1,300 mm x 1,300 mm) to accommodate the largest Poly Pipe Weld test sample.

Want to know more about LMATS Waterjet Cutting for Poly Pipe Weld Testing and how it can assist you simply call us or contact us through our form